High productivity at contained cost in high power and high-speed milling

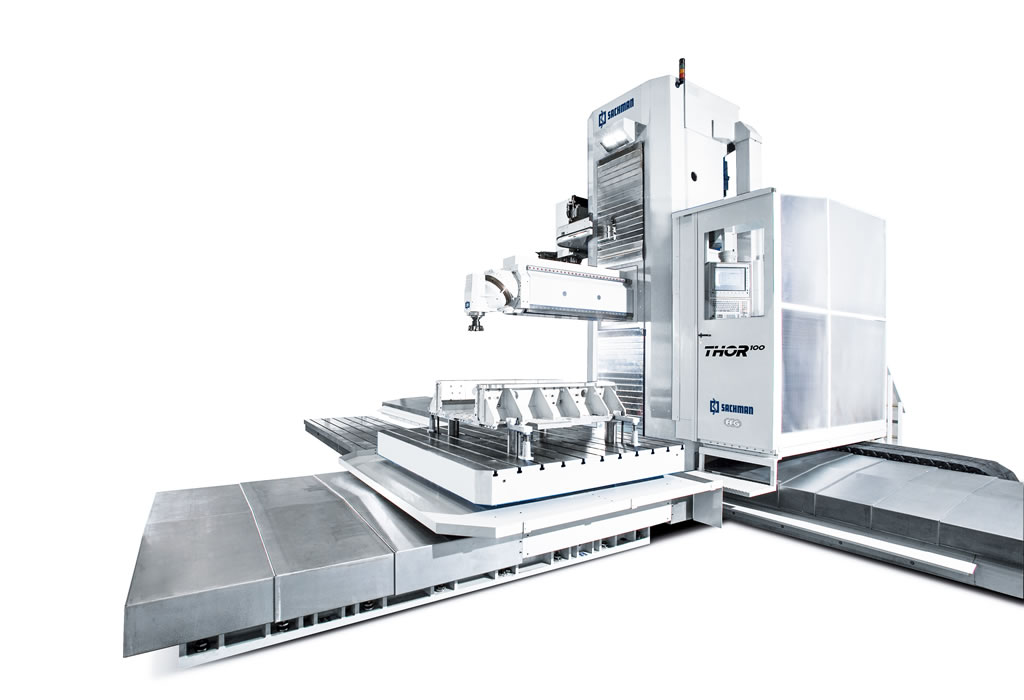

Sachman THOR 100/200 are medium/large-size universal horizontal milling centres for 3/4/5-axis machining, characterised by a thermo-symmetric moving column structure, with guideways optimized positioning and orientation to grant maximum rigidity and compactness; the barycentric position of the Z-axis saddle ensures high accuracy and the innovative high-efficiency axis kinematics allows excellent dynamic performance.

Particular attention has been paid to the ergonomics of the operator place, which allows perfect monitoring of the machining operations, including direct access to the workpiece, if necessary, in totally safe conditions.

THOR 100/200 milling centres ensure a great degree of application flexibility and are the perfect solution for end-users seeking technological excellence at low hourly and operating costs, in the fields of general precision engineering, energy, medium and large mould and die and in the aerospace sector.

Technical features

THOR 100

- Longitudinal X-Axis 4000-7000 mm +Δ 1500 mm

- Vertical Y-Axis 2000-2500-3000 mm

- Transversal Z-Axis 1200-1500 mm

- Speed up to 25 m/min

THOR 200

- Longitudinal X-Axis 3500-6500 mm +Δ 1500 mm

- Vertical Y-Axis from 4000 to 6000 mm

- Transversal Z-Axis 1200-1500-2000 mm

- Speed up to 22 m/min

A wide range of heads and spindles to best meet your machining requirements:

- Up to 1500 Nm for heavy-duty machining

- Mechanical vertical/horizontal/fork-type twist heads

- Electrospindle fork-type twist heads

- Automatic head changing system (BUSS)

- Wide selection of fixed, rotary, or roto traversing worktables (B and W axes), with different loading capacities

- Wide range of tool magazines available:

- Direct chain from 16 to 40 positions

- Chain-type on board machine with double gripper change arm from 40 to 80 positions

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and probing systems

- Fixed or mobile operator platforms for the best accessibility and visibility of large components

- Automatic pallet systems