- Cast iron structure to provide maximum stiffness and dampening, especially for titanium machining

- Crossbeam vertical movement to ensure constant accuracy on the whole operating volume

- Very high-volume stock removal rate on tough materials

- Compact and ergonomic full machine enclosure and minimum foundation requirements

Applications

Heavy-duty milling of structural parts in tough materials

Jobs TARKUS 2.0 is a double-column milling centre with moving table specifically designed to offer end-users in aerospace, heavy engineering and mould and die sectors excellent productivity in all machining stages from 3- to 5-axis roughing to finishing operations on structural components made of particularly tough materials such as titanium, Inconel, stainless steel and HRSA alloys.

TARKUS 2.0 is therefore able to ensure high quality machining at very competitive operating costs for a quick return on investment. All machine structures are made of cast iron in order to enhance their dampening characteristics. In particular, the machine crossbeam moves entirely vertically with the acceleration and speed of a conventional axis but with much greater rigidity than machines with a vertical ram and providing constant accuracy throughout the whole working volume.

TARKUS 2.0 features a full compact and ergonomic safety cabin with large windows that provide an easy view of cutting operations. The top cover fitted with vapor suction units, permits to contain chips during machining and facilitates deflection into the chip evacuation system, while its automatic opening allows part loading/unloading.

Technical features

- X-Axis 4500-6000 mm

- Cast-iron moving table with great loading capacity, integrated in the machine structure

- Y-Axis 2100-2600 mm

- Z-Axis 1000 mm

- Speed up to 20 m/min

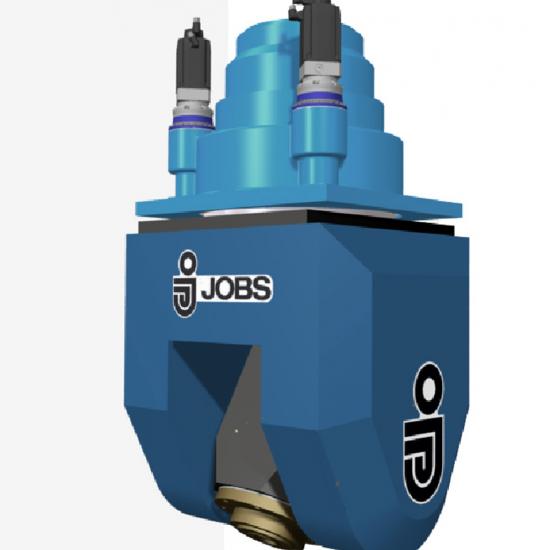

A choice of heads specifically conceived for heavy-duty machining on tough materials:

- Mechanical vertical heads up to 3400 Nm

- Fork-type twist heads for full 5-axis machining up to 1200 Nm

- Automatic head changing system (BUSS)

- Several tool magazines available:

- Single/double chain with double gripper change arm from 48 to 96 positions

- Rack type with large storage capacity for up to 300 tools

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and coding systems, probing systems

- Dual-table configuration for pendulum machining with workpiece load/unload in masked time

- Automatic pallet systems