Knocking out machining costs: two versions, endless possibilities

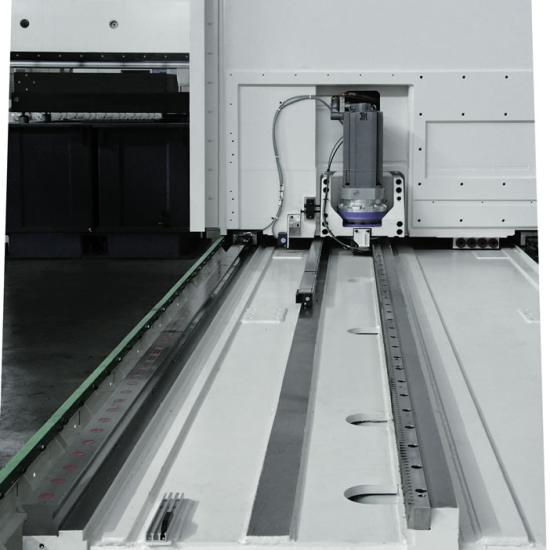

Sachman FRAZER is a medium-size universal horizontal milling machine with moving column for 3/4/5-axis machining, available in two versions: FRAZER BOX and FRAZER OPEN.

FRAZER BOX, completely enclosed, has a longitudinal moving column structure with strokes ranging from 3 to 5 metres and transversal movement realised by means of a ram, allowing pendular machining on two distinct working areas or the machining of a single component with a significant longitudinal development. The wide range of configurations available make FRAZER BOX suitable mainly for the general mechanical and mould and die subcontracting market, ensuring extremely competitive hourly costs.

FRAZER OPEN model is different for its perimeter fence and longitudinal travels of up to 30 metres, which offer greater possibilities for integrating frontal units such as fixed, rotating or rototranslating worktables and customised solutions to meet the needs of a wide range of customers such as subcontractors and large industrial groups in the aerospace and general engineering sectors.

Technical features

BOX

- Longitudinal X-Axis 3000-4000-5000 mm

- Vertical Y-Axis 1500-2000 mm

- Transversal Z-Axis 1100 mm

- Speed up to 35 m/min

OPEN

- Longitudinal X-Axis 4000-6000-7000 mm +Δ 1500 mm

- Vertical Y-Axis 1500-2000-2500 mm

- Transversal Z-Axis 1100-1300 mm

- Speed up to 35 m/min

- Universal indexed/continuous milling heads or continuous fork-type twist heads with electrospindle are available.

- Rotary table built in the fixed table

- Wide selection of rotary and rototraversing tables of various dimensions and loading capacities (for OPEN version only)

- Wide range of tool magazines available:

- Disk-type with mechanical hand 24 or 30 positions

- Horizontal floor-mounted chain-type 40 or 60 positions

- Vertical chain-type, mounted on column, 40 or 60 positions (for OPEN version only)

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and probing systems