Jobs LINX line is highly appreciated in all those sectors where a medium-large working volume and the high dynamics ensured by linear motors represent a competitive advantage.

Available in various versions and with different set-ups, the LINX family has recently been extended with the arrival of the LINX CUBE.

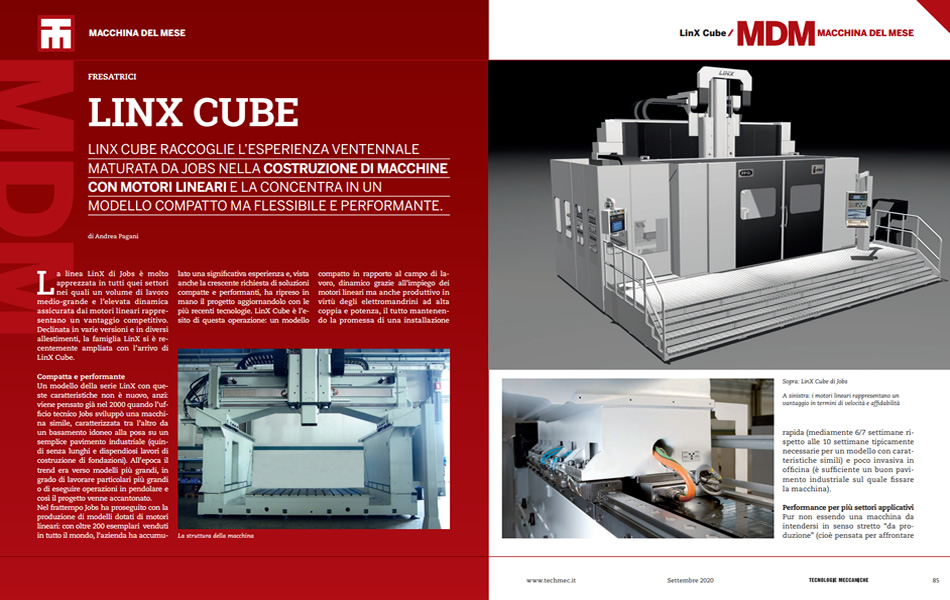

Compact and performing

A model of the LINX series with these characteristics is not new, on the contrary: it was already conceived in 2000 when Jobs R&D dept. developed a similar machine, characterized among other things by a bedplate suitable for installation on a simple industrial floor (therefore without long and costly foundation construction work).

At that time, the trend was towards larger models, capable of machining larger parts or performing pendular operations, and so the project was shelved.

In the meantime, Jobs continued with the production of models equipped with linear motors: with over 200 units sold worldwide, the company has gained significant experience and given the increasing demand for compact and high-performance solutions, has taken over the project updating it with the latest technologies.

LINX CUBE is the result of this operation: a compact model in relation to the working field, dynamic thanks to the use of linear motors but also productive thanks to the high-torque and high-power electrospindles, all while keeping the promise of a quick installation (on average 6/7 weeks compared to the 10 weeks typically required for a model with similar characteristics) and non-invasive in the workshop (a good industrial floor on which to fix the machine is sufficient).

Performance for multiple application areas

Although not strictly speaking a "production" machine (i.e., designed to cope with very large batches), it is decidedly productive from the point of view of speed in machining complex parts. These range from single pieces, such as moulds and prototypes, to small batches (as in the aeronautical sector, where in some cases up to 50 pieces/month can be produced).

LINX CUBE can be defined as high-performance in the broadest sense of the term: it is not only a question of linear axis speed (reaching 70 m/min), but also of swarf removal volumes. The secret lies in the available electrospindles, which provide high torque and power values.

In this way, LINX CUBE proves to be suitable to face the challenges of aerospace and automotive (specifically moulds and prototypes), but also those of general mechanics. In this regard, users in general mechanics are - understandably - very selective: think of machine manufacturers, the energy sector, the semiconductor sector, defence and in general anywhere there are complex parts that require 5-axis machining (continuous or positioned).

A modular project

Although LINX CUBE is characterized by compact dimensions, it can be configured with X stroke up to 6,500 mm: the structure has been designed to be modular in size and equipment, in order to best meet the specific needs of each user.

The first challenge the technicians faced was to build a machine that did not require a foundation, but only an industrial floor with good characteristics on which to fix it.

The lower part is therefore self-supporting, in welded carpentry sized to ensure maximum rigidity and with stress-relieving treatments to guarantee the absence of internal tensions.

For the upper part, the most modern FEM analysis technologies have been used and further tests and verifications have been carried out using a virtual machine (digital twin).

Combining the two parts together very high own frequencies are also obtained, useful to avoid the onset of harmful vibrations during the most demanding operations.

The result is an extremely dynamic kinematics capable of reaching 70 m/1 and an acceleration of 5 m/s2.

LINX CUBE is also quick and easy to install in the customer's workshop: while on average, other gantry models take about 10 weeks to install, with LINX CUBE it only takes 6 or 7. A considerable saving that has a positive effect on the cost of supplying the system.

The initial project envisaged a lighter structure, designed for medium removal rates. Today's version, on the other hand, has been strengthened in a smart way in order to be able to deal with aluminium, composites, steel, and cast-iron thanks also to a series of appropriately sized electrospindles. Obviously, for each requirement it is necessary to equip the machine in the best possible way: with aluminum, for example, conveyors capable of handling the volumes of chips that are typically obtained on this material will be essential. For composite, on the other hand, an efficient suction system will be needed. These are just some of the options and modules designed by Jobs to make the LINX CUBE perfectly configurable for each need.

Linear motors: not only speed

In 20 years of linear motors use a theme has emerged decisively: if at the beginning the main plus was linked to axis speed, dynamics, and accelerations to reduce cycle times, today it is undeniable that even machines equipped with traditional motors are able to achieve very good dynamics. So why choose a model equipped with linear motors? The answer is reliability: in these 20 years of direct experience with hundreds of models installed all over the world, it has emerged that even the first machines born in 2000 are still used without particular problems. Apart from normal maintenance, in fact, the transmission with linear motors is not subject to wear and therefore performance does not deteriorate and remains constant over the years.

When rack and pinion are present instead, it is necessary to recover the backlash that is triggered by the natural wear of the components and to replace them at a certain frequency.

If on the one hand linear motors require a special cooling system to operate at their best, on the other hand this brings with it a stabilization of the machine structures over time. Jobs uses refrigerators able to regulate with great accuracy the temperature of the fluids introduced in the various circuits: this allows keeping the operating temperature range under strict control, thus limiting dimensional errors triggered by the elongation of the components or of the structure. Of course, there are direct measuring systems both on the linear axes (optical scales) and on the rotary ones (absolute encoders).

Power and Torque

Jobs offers five different electrospindles and three heads that can be combined together.

The two 15,000 rpm models offer 44 kW of power and a maximum torque of 200 Nm or 82 kW and 391 Nm, respectively. Then we move on to the 24,000-rpm version (47 kW and 72 Nm of torque) and the 27,000-rpm version (with 40 or 63 kW and 63 Nm of torque) up to the top of the range 30,000 rpm, 156 kW and 88 Nm of torque.

On the head side, the T2D-06 is a fork-mounted twist model (±200° in the C-axis and +120°/-110° in the A-axis) that uses torque motors with 1,240 Nm (C-axis) and 821 Nm (A-axis).

Similar characteristics for the T3K, a fork head that provides 1,200 Nm of torque in C and A axes.

Finally, TT300 is a continuous head with 2,000 Nm of torque in A and C and an excursion of ±200° and -120°/+95° respectively.

All the heads are equipped with Heidenhain direct encoders to ensure maximum operating accuracy.

Ready for Industry 4.0

The available numerical controls are Siemens 840D sl (soon also Sinumerik One), Heidenhain TNC 640 and, on request, Fanuc.

From this point of view the prearrangement to the functions of Industry 4.0 is total. The machine is properly sensorized and makes the data available so that the customer can manage them according to the company software at his disposal.

Apart from the thermal sensors that constantly detect the temperature inside the machine, the most critical component - and therefore the one that requires the most attention - is the electrospindle. It is in fact "in the front line" during chip removal and is the one that can be subject to collisions; it is the point where cutting efforts are concentrated, the highest temperatures develop, and vibrations impact the quality of machining (as well as the useful life of the tool).

Great attention to details

Another increasingly important issue in industry is efficiency and consequent energy saving.

LINX CUBE exploits all the latest technologies to limit the consumption of the most energy-demanding components (such as refrigerators, motors, etc.) in order to contain consumption.

The design is also new: the line is modern but ergonomic and practical for the operator. The opening is wide, and the LED lights improve visibility in every point of the working field, while the roof can be automatically opened to load bulky pieces using the overhead crane. There is also the possibility to mount a quick-release roof: in particular, conditions, the customer can thus exploit the entire travel of the machine by quickly removing the top cover and thus carry out work on large pieces or to access undercut points.

Given the performance promised by LINX CUBE, it is essential to ensure adequate supply of lubricating and cooling fluids. The machine can mount pumps up to 80 l/min and 70 bar pressure with 2,500 litre tanks but can also work with spray mist applications inside and outside the tool.

Good availability of places in the tool magazine, capable of accommodating 24, 32, 64 or 96 tools with HSK-A63 and HSK-100 tapers. If necessary, it can be further extended with external magazines and robots (linear or anthropomorphic).